Motor control has different requirements and purposes depending on the type of motor and the occasion of motor use. For electric motors, motor control is used to achieve fast starting, fast response, high efficiency, high torque output and high overload capacity of the motor.

Contactors For Motor Control

Contactors are used in motor control to control electric motors or other load circuits (electric heaters, welding machines, lighting equipment); they can break and turn on load circuits under normal conditions; they have the ability to withstand fault currents under fault conditions; the contactors themselves do not have overload and short-circuit protection and have a low-voltage release function; they can be used to frequently turn on and break circuits and control circuits over long distances.In short, the role of contactors in electromechanical control is:

1. remote operation

2. frequent operation

3. turn on and break circuits

4. high current control

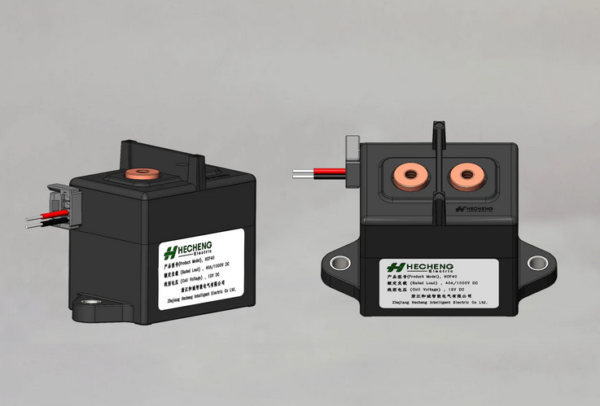

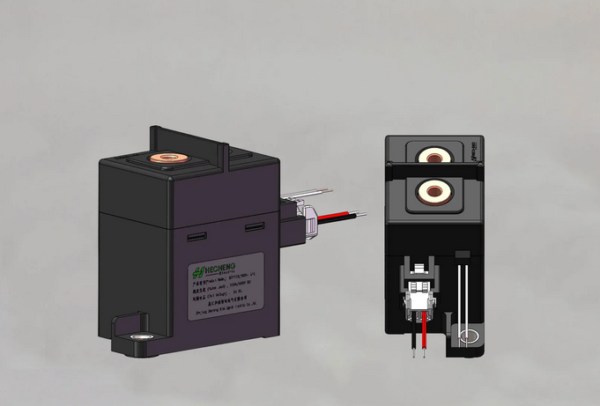

HDCPY series HDCPY124040 HCDPY22430 HCDPY32440 HCDPY42430 , SA series and HC6-09-18, HC6-25-40, HC6-40-65, HC6-75-100, etc. are currently produced by Hecheng Electric Co.

DC Relay For Motor Control

Relays are automatic switching components with isolation function, widely used in remote control, telemetry, communication, automatic control, mechatronics and power electronics, and are one of the most important control components.

Relays generally have an inductive mechanism (input section) that reflects certain input variables (e.g., current, voltage, power, impedance, frequency, temperature, pressure, speed, light, etc.); an actuator (output section) that provides “on” and “off” control of the controlled circuit; and an intermediate mechanism (drive section) that couples and isolates the inputs, processes the functions, and drives the outputs. Between the input and output parts of the relay, there is an intermediate mechanism (drive part) that couples and isolates the input quantity, processes the function and drives the output part. As control elements, in summary, relays serve several purposes:

1. Expanding the control range: For example, when a multi-contact relay control signal reaches a certain value, it can switch, open and turn on multiple circuits at the same time according to the different forms of contact groups.

2. Amplification: For example, sensitive relays, intermediate relays, etc., with a very small amount of control, you can control a very high-power circuit.

3. Integrated signals: For example, when multiple control signals are fed into a multi-winding relay in a prescribed form, they are compared and integrated to achieve a predetermined control effect.

4. Automatic, remote control, monitoring: For example, relays on automatic devices, together with other electrical appliances, can form programmed control lines, thus achieving automated operation.

At present, Hecheng Electric Co. has developed and put into production the following relays: HCF/200/250/300 for charging station, HCF40/150/200 for charging pile, HCF40/200 for photovoltaic, HCF200/300/400 for wind energy, etc.